A very attractive and permanent case to hold a deck of cards can be made from a small sheet of transparent plastic. The case may be personalized by the application of a jigsawed monogram or a single initial which is cemented to the surface.

A very attractive and permanent case to hold a deck of cards can be made from a small sheet of transparent plastic. The case may be personalized by the application of a jigsawed monogram or a single initial which is cemented to the surface.

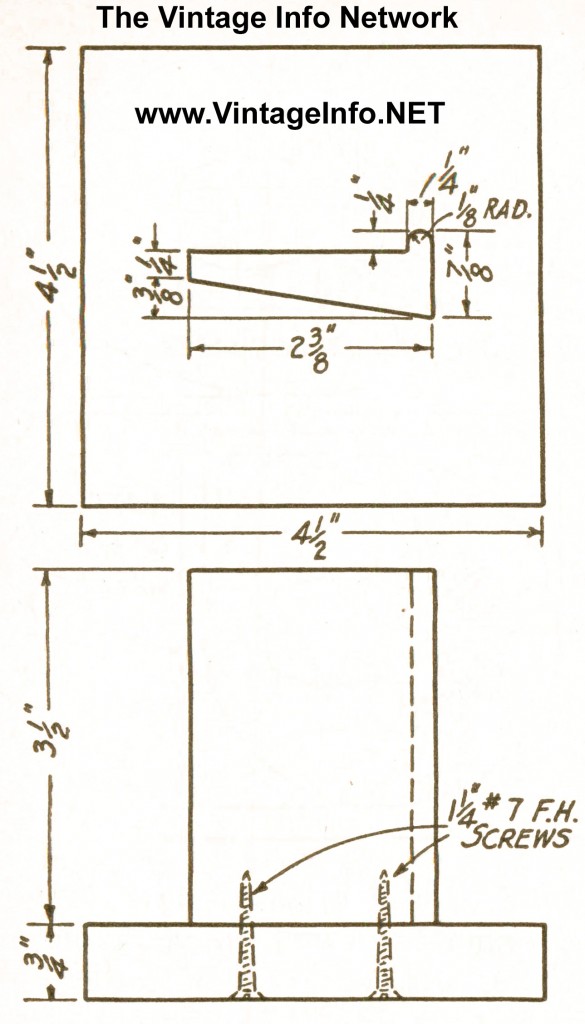

Making of the case requires the use of a wood form for shaping the plastic.

As shown in the photograph and drawing the form on which the case is shaped is made of a piece of close-grain wood measuring 7/8″ thick, 2 3/8″ wide and 3 1/2″ long. One face of this piece is tapered from a point 3/8″ below the face to the opposite corner. The line of this taper should be laid out on one end of the block. The bench saw table is tilted to the required angle for cutting the taper. Since the average bench saw used in the home workshop is not capable of cutting to a depth of 2 3/8″, the cut may have to be made in

two operations; the first cut is made to the maximum depth of the saw blade and the second cut is made by inverting the stock and setting the rip fence on the opposite” side of the saw blade before feeding the stock.

The opposite face of the stock is rabbeted to a depth of 1/4″ and to a width of 2 1/8″. The lip left on the edge of this face is rounded at a radius of 1/8″ as shown in the drawing. The shaping of this lip may be done by hand with a plane and sandpaper, or the work may be done on a shaper equipped with a cutter of the required size. The form now must be sanded.

The form is mounted to a base made of 3/4″ stock at least 4 1/2″ square. Two

The form is mounted to a base made of 3/4″ stock at least 4 1/2″ square. Two

flathead wood screws 1 1/4″ long are driven through the base at points where

they will enter the form. The base of the form may be held in the rise or may be clamped to the bench when the plastic is being placed around the form.

Two additional pieces of wood at least 1/2″ thick, 2″ wide and 3 1/2″ long will

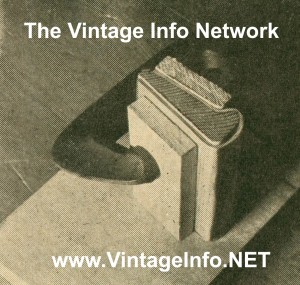

be needed to hold the plastic to the form as shown in the photograph.

A sheet of plastic 1/16″ thick, 3 1/2″ wide and 5 1/2″ long will be required for the case. The plastic is placed in an oven which has been heated to a temperature of about 220 degrees F. When soft and pliable the plastic is

removed from the oven and placed around the form. The blocks are

placed on each side of the plastic and a clamp is applied as shown in the

photograph. When cool, the case is removed from the form.

After the monogram has been jigsawed from a sheet of plastic, it should be colored by being dipped in dyeing solution of whatever color is desired.

The finished monogram is applied to the case with special plastic cement.

[phpbay] antique playing cards, 9 “,”[/phpbay]